You have no items in your shopping cart.

Filter by price

SHIELD

SHIELD GLOBAL is the leading manufacturer of HDPE, steel pipes and conduits in accordance with the Civil Defense regulations. Our HDPE products are manufactured in compliance with global standards, according to ISO 4427/4437 (European) & AWWA C906 (American), approved as per UL & FM standards, while our steel pipes are manufactured in compliance with ASTM, UL and FM approvals. Our piping systems are best for municipal, industrial, marine, agricultural and fire-fighting applications

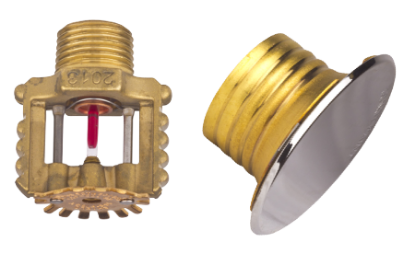

Sprinkler Head 68 Deg. Pendent, 1/2" NPT, Chrome Finish, Standard Response, UL/ULC/FM/Watermark Approved, Model: SD1010SR - Shield

Sprinkler design incorporates state-of-the-art heat responsive frangible glass bulb design (standard or quick response) for prompt precise operation

17.00 (AED)

Concealed Spray Pendent Sprinkler K Factor : 5.6 Nominal Thread Size : 1/2" NPT

Sprinkler design incorporates state-of-the-art heat responsive frangible glass bulb design (standard or quick response) for prompt precise operation

33.00 (AED)

Conventional Sprinkler

Sprinkler design incorporates state-of-the-art heat responsive frangible glass bulb design (standard or quick response) for prompt precise operation.

Vertical Sidewall Sprinkler

Sprinkler design incorporates state-of-the-art heat responsive frangible glass bulb design (standard or quick response) for prompt precise operation.

Horizontal Sidewall Sprinkler

Sprinkler design incorporates state-of-the-art heat responsive frangible glass bulb design (standard or quick response) for prompt precise operation.

31.00 (AED)

Pressure Gauge SD-P1

SD-P1 Pressure Gauge are specifically designed for Fire Sprinkler Services. The pressure gauge is UL Listed and FM approved. It has corrosion resistant polished stainless steel case and Bezel and Brass wetted parts. The dial has pressure reading in KG/SQCM and PSI. The gauge window is hardened glass. The pressure gauge must be mounted by square provided for spanner grip on the socket and not by turning the case. Turning of case will damage the gauge. Use PTFE tape around male threads of the gauge for sealing. Pressure gauge must be mounted in vertical position and isolated with valve or cock. The pressure gauge must be handled with due care for best results, the gauge should be stored in the original packing in which it has been shipped. It is advisable to ship the gauge in the same package for future transit. The pressure gauge, which is visibly damaged, should not be installed. It is recommended that the pressure gauges must be inspected regularly for possible corrosion or damage. The gauge must be periodically calibrated as per requirement or as per local authority having jurisdiction.

99.00 (AED)